Energy-saving submersible agitators TSR

CSA / UL certified

Technical Properties

| Power range | 10-22 HP (7.5-16 kW) |

|---|---|

| Mains frequency | 60 Hz |

| Axis thrust | up to 967 lbf (4,300 N) |

| Circulating rate | up to 19,773 gal/min (4,491 m³/h) |

| Propeller diameter | up to 37.8“ (960 mm) |

| Coolant/medium temperature | max. 60 °C |

| Mechanical seal | SiC/SiC pairing |

| Immersion depth | max. 20 m |

Technical Specifications

| Type | Power rating | Frequency | Current rating* | Propeller speed | Axial thrust | Circulating rate ** |

|---|---|---|---|---|---|---|

| HP (kW) | Hz | A | rpm | lbf | gal/min | |

| TSR 74-160 | 10 (7.5) | 60 | 11.5 | 190 | 540 | 12,927 |

| TSR 114-160 | 15 (11) | 60 | 17.1 | 190 | 765 | 16,665 |

| TSR 166-160 | 22 (16) | 60 | 28.5 | 190 | 967 | 19,773 |

| TSR 166-160 | 22 (16) | 60 | 23 *** | 190 | 967 | 19,773 |

| * At 480 V, other voltages on request ** Circulating rate according to ISO 21630:2007 *** At 600 V |

DIMENSIONS AND WEIGHTS

| Type | A | B | C | D | E | F | G | Weight* |

|---|---|---|---|---|---|---|---|---|

| in | in | in | in | in | in | in | Ibs | |

| TSR 74-160 | 33.1 | 26.9 | 57.9 | 53.1 | 19.1 | 20.3 | 4.8 | 448 |

| TSR 114-160 | 35.8 | 28.9 | 57.9 | 53.1 | 19.1 | 20.3 | 4.8 | 490 |

| TSR 166-160 | 37.8 | 30.8 | 57.9 | 53.1 | 19.1 | 20.3 | 4.8 | 534 |

* Agitator without carriage

Materials

| Housing | GG25 |

|---|---|

| Seal holder | Stainless steel 1.4301 (V2A) |

| Connecting elements | Stainless steel 1.4301 (V2A) |

| Motor shaft | 1.7225 |

| Propeller | Stainless steel 1.4301 (V2A) |

| Mechanical seal | Silicon carbide |

| Carriage | Stainless steel 1.4301 (V2A) |

| Corrosion protection | UL approved special coating |

Safety

- For use in potentially explosive atmospheres, TSR submersible agitators are available with the "pressure-tight encapsulation" ignition protection type (AEx db for the USA and Ex db for Canada) in accordance with CSA / UL (class 1 zone 1).

- Temperature monitoring in the motor winding

WIDE RANGE OF APPLICATIONS

Applications are above all in municipal and industrial waste water treatment, biogas generation, industrial process technology and agriculture. In addition to avoiding deposits and floating layers, the devices can also be used for a wide range of agitating and mixing tasks.

HARSHEST AMBIENT CONDITIONS

For use in potentially explosive atmospheres, TSR submersible agitators are available with the "pressure-tight encapsulation" ignition protection type (AEx db for the USA, and Ex db for Canada) according to CSA/UL (class 1 zone 1). The maximum medium temperature is 60 °C.

APPLICATIONS

-

TSR type submersible agitator in covered final storage -

Gas-tight cover feed-through for submersible agitator -

Submersible agitator in open storage tank -

Submersible agitator with installation fitting -

Submersible agitator with gas-tight wall

feed-through -

Submersible agitator with adjustable carriage

INNOVATIVE PROPELLER GEOMETRY

A decisive feature for comparing the efficiency of agitators is what is referred to as the first performance number as a quotient of the generated thrust force and the energy observed at the operating point. The propeller geometry that has undergone further development in the streisal fluid mechanics laboratory involving the use of the latest measuring technology and has been optimised in the test tank (large scale) means that enormously high thrust values are possible with a low power consumption. This means much lower and operating costs!

Agitator Technology Centre

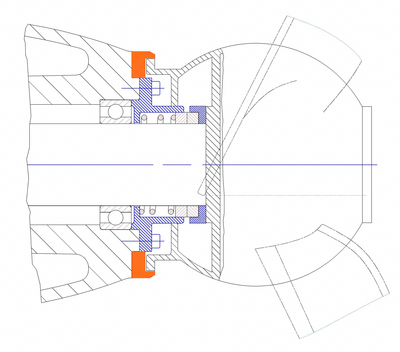

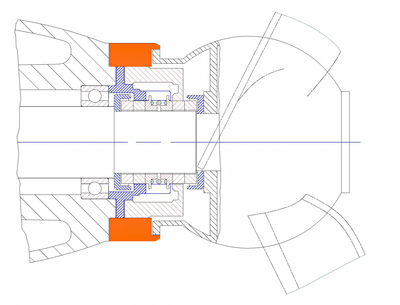

MECHANICAL SEAL SYSTEM

It has been shown in practice that reliability and durability of shaft seals are decisive criteria for trouble-free operation. In particular in media with relatively coarse or abrasive solids, long-fibre constituents and disruptive substances (such as plastic strands, films, etc.), the unique and patented seal system from streisal offers a series of advantages:

- Highly wear-resistant streisal Seal Guard mechanical seal made of silicon carbide

- Upstream labyrinth seal to prevent penetration by disruptive substances

- Submersible agitator housing with easily replaceable wearing ring

- Mechanical seals are protected by being mounted in a stainless steel holder

- Spring elements on the inside, not in contact with the medium