Efficient agitator technology

in use around the world

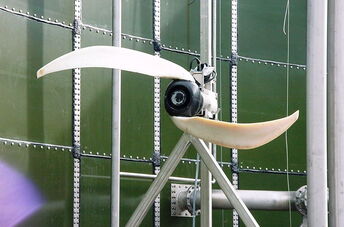

Since 1988, streisal has been delivering agitators and mixing systems to customers worldwide. The many plants that we have equipped include biogas and sewage treatment plants as well as innumerable applications in industrial process technology. We will be happy to send you detailed information for your specific requirement on request. Please get in touch with us about this.

PROJECTS AND

AS A FIRST IMPRESSION, YOU CAN FIND SOME EXAMPLES

OF OUR WORK BELOW:

Since 1988, streisal has been delivering agitators and mixing systems to customers worldwide. The many plants that we have equipped include biogas and sewage treatment plants as well as innumerable applications in industrial process technology. We will be happy to send you detailed information for your specific requirement on request. Please get in touch with us about this.

As a first impression, you can find some examples of our work below.

Pommerehne, Germany

Turbo mash with streisal Hydrobull® mixing system as a step towards increasing flexibility of the biogas plant.

Lana, Italy

Three new digesters with energy-efficient vertical agitators for the AD Lana plant expansion.

Dole Surallah, Philippines

Digester with streisal Biobull® agitators generate biogas from pineapple waste.

ZooShare, Toronto, Canada

Manure from the zoo and inedible food waste are turned into renewable electricity in the biogas plant.

AHI SULUOVA BIOGAS PLANT, TURKEY

The entire plant is equipped with agitator technology from streisal: mixing pits, digesters, secondary digesters and fermentation residue storage. As a result of the low self-generated electricity requirement and great ease of servicing, streisal was the preferred choice for the Turkish biogas plant operator.

MODERNISATION OF AGITATOR TECHNOLOGY IN ESCHEDE, GERMANY

Existing submersible motor agitators are replaced by energy-efficient, slow-running Biobull® digester agitators from streisal. This makes it possible to use difficult substrates such as solid manure or grass silage, and saves electricity costs.

DIGESTION TOWER AGITATOR IN SCHONGAU, GERMANY

Expansion of the sewage treatment plant at a cheese factory operated by Hochland. The agitator for the new digestion tower is a streisal vertical Biobull® type BIOS 34 V.

BIOGAS PLANT IN TREIZE VENTS, FRANCE

The entire plant is equipped with agitator technology from streisal: pre-pit, digester, secondary digester and final storage. The plant is supplied almost exclusively with manure – only the streisal Biobull® can cope with this.

DIGESTER ON HOKKAIDO, JAPAN

In Japan, particular emphasis is placed on energy-efficient technology, thereby explaining the choice of an agitator from streisal.

HYBRID POWER PLANT IN WITTENHOF, GERMANY

The power plant generates hydrogen with the help of wind energy. When there is a high demand for electricity, the hydrogen is mixed with biogas and converted into electricity with neutral CO2 emissions in combined heat and power plants, then the electricity is supplied to the grid. streisal GmbH supplies agitator technology for the digesters of the biogas plant.

BIOGAS IN INDIANA, USA

Manure, food waste and other organic matter are used for generating carbon-neutral electricity. The 5,000 m3 stainless steel digester is operated with streisal agitators.

SEWAGE TREATMENT PLANT IN RANKWEIL, AUSTRIA

The sewage treatment plant operated by Rauch, the fruit juice manufacturer, is also equipped with a slow-running, large-blade submersible agitator of the ATP type.

HYDROLYSIS SYSTEM IN SCHLESWIG, GERMANY

To replace the outmoded loading technology, the Schleswig utility company decided to use a hydrolysis system supplied by Innovas. Both mashing tanks are agitated by streisal Hydrobull® mixing systems and the supply tank features a TSR submersible agitator.

REPOWERING WITH BIOBULL® IN PLÄTZ, GERMANY

A streisal Biobull® is being retrofitted to the combination storage tank made of enamelled steel.

BIOGAS PLANT IN WILTSHIRE, UK

The mixing pit is provided with a streisal Hydrobull® mixing system. The agitating tasks in the digester are carried out by two Biobull® digester agitators.

SLOW-RUNNING SUBMERSIBLE AGITATORS IN OBEROTTMARSHAUSEN, GERMANY

In the Lechfeld sewage treatment plant, streisal ATP flow accelerators have been operating in the 4 activation tanks since 2003.

BIOSUBSTRATOR® ROD AGITATOR IN KÜSSNACHT, SWITZERLAND

The new digester of a biogas plant is being equipped with Biosubstrator® and Biobull® from streisal. In the secondary digester, an existing submersible motor agitator is being replaced by an energy-saving Biobull®.

BIOGAS PLANT IN KRÁĽOVSKÝ CHLMEC, SLOVAKIA

Digesters 1 and 2 are provided with agitator technology from streisal.

BIOGAS PLANT IN MITROVAC, CROATIA

The entire plant is equipped with agitator technology from streisal: streisal Hydrobull® mixing systems are used in both mixing pits; digesters and secondary digesters are given Biobull® propeller agitators as well as efficient, medium fast-running submersible motor agitators.

DIGESTER AGITATORS IN ITALY

As a result of the low self-generated electricity requirement and great ease of servicing, streisal Biobull® units have become the preferred choice for many Italian biogas plant operators. This reference plant is operating in Bagnocavallo.

SUBMERSIBLE AGITATOR OF THE TSR TYPE IN ARAD, ROMANIA

A streisal submersible motor agitator of the latest TSR series is installed in this stainless steel tank.

VERTICAL AGITATOR IN FRASTANZ, AUSTRIA

The sewage treatment plant operated by the Elfer foodstuffs company is equipped with agitator technology from streisal. A vertical Biobull® is installed in the digestion tower.