Compact submersible agitators

with direct drive TRV

TECHNICAL PROPERTIES

| Power range | 1.1 kW |

|---|---|

| Mains frequency | 50 Hz |

| Circulating rate | 300 m³/h |

| Propeller diameter | 220 mm |

| Coolant/medium temperature | max. 40 °C |

| Mechanical seal | SiC/SiC pairing |

| Immersion depth | max. 20 m |

TECHNICAL SPECIFICATIONS

| Type | Power rating | Current rating | Propeller speed | Axial thrust | Circulating rate * |

|---|---|---|---|---|---|

| kW (P2) | A | rpm | N | m³/h | |

| TRV 16-220 | 1.1 | 3.4 | 900 | 365 | 300 |

| TRV 16-270 ** | 1.1 | 3.4 | 550 | 293 | 330 |

| TRV 16-400 ** | 1.1 | 3.4 | 220 | 249 | 450 |

| Motor 400 V, rated frequency 50 Hz, index of protection IP 68 | * Circulating rate according to ISO 21630:2007 ** In operation with frequency inverter |

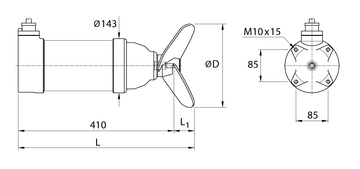

| Type | D | L | L 1 | Weight |

|---|---|---|---|---|

| mm | mm | mm | kg * | |

| TRV 16-220 | 220 | 465 | 55 | 27.5 |

| TRV 16-270 | 270 | 476 | 66 | 28 |

| TRV 16-400 | 400 | 492 | 82 | 28.5 |

* Agitator without carriage

MATERIALS

| Housing | Stainless steel 1.4301 (V2A) |

|---|---|

| Bearing plates | Stainless steel fine casting 1.4308 |

| Bearing plates | Stainless steel 1.4301 (V2A) |

| Propeller shaft | 1.4104 |

| Propeller | Stainless steel 1.4301 (V2A) |

| Mechanical seal | Silicon carbide |

SAFETY

- Temperature monitoring in the motor winding

- Monitoring of the sealing system by leakage probe

SMALL AGITATOR TANKS AND PONDS

The fast-running submersible agitators of the TRV type are suitable above all for swirling up deposits and solids, for example in pumping stations, equalisation or retention tanks as well as for industrial mixing of all kinds of substances in relatively small agitating tanks.

EXTREME OPERATING CONDITIONS

The universally applicable submersible motor agitator has a high-alloyed stainless steel housing and opens up entirely new applications – even for adhesive, highly aggressive and abrasive media. Seal elastomers are available either as fluorinated rubber (Viton) or as perfluorelastomers (Kalrez, Prafluor).

STURDY STAINLESS STEEL HOUSING

The robust small submersible motor agitator has a housing made of high-alloyed stainless steel which can be used even for difficult agitating and mixing tasks.

MAXIMUM PERFORMANCE IN THE SMALLEST SPACE

With its compact design, the submersible agitator is also suitable for tight installation openings for subsequent installation.

FLEXIBLE ADAPTATION TO THE MATERIAL BEING MIXED

When operated with a frequency inverter, variable speeds and propeller diameters allow for flexible adaptation to the medium.