High-performance agitating systems:

Maischebull®/Hydrobull®

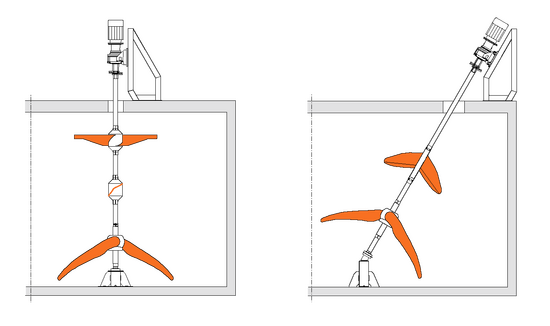

- Vertical/inclined agitators

- Biobull

- Vertical Biobull

- Biosubstrator

- Maischebull / Hydrobull

TECHNICAL SPECIFICATIONS

| Type | Power rating | Current rating | Rotation speed |

|---|---|---|---|

| kW | A | rpm | |

| BIOE 114 (M)D | 11 | 21.5 | 38 |

| BIOE 154 (M)D | 15 | 31 | 38 |

| BIOE 184 (M)D | 18.5 | 36.6 | 38 |

| BIOE 304 (M)D | 30 | 55 | 55 |

Motor 400 V, rated frequency 50 Hz, index of protection IP 54

DIMENSIONS AND WEIGHTS

| Propeller diameter | 1,500 mm to 2,650 mm (also with different profiles depending on the task) |

|---|---|

| Required cover opening for passing through the agitator shaft | Core hole 300 – 600 mm |

| Cover opening required for putting in other components | approx. 1,000 x 800 mm |

| Total weight | approx. 1,100 – 1,500 kg depending on version |

MATERIALS

| Gas-flushed parts in the tank | Stainless steel 1.4571 (V4A) |

|---|---|

| Parts outside the tank | Galvanized, painted or coated |

| Bottom bearing | Silicon carbide mechanical seal |

| Propeller (dia. 2,300 – 2,650 mm) | High-strength, wear-resistant polymer with steel core |

| Propeller (dia. 1,500 – 1,900 mm) | Stainless steel 1.4301 (V2A) |

SAFETY

- ATEX, IECEx and UL/CSA-certified versions for use in explosion protection zones 1 and 2

- Frequency inverter with parameterised safety software (torque limiting, coupling break detection, etc.)

- "streisal SafeGuard" (optional): automatic torque monitoring and control system for changing filling levels

- Shear-pin coupling as the final predetermined breaking point

MIXING SOLIDS

The powerful, large propeller agitators of the Maischebull®/Hydrobull® type make it possible to mix or stir in large quantities of solids in pre-pits, mashing pits and hydrolysis tanks.

Especially with difficult substrates containing fibrous components such as solid manure or grass, this reliable and low-wear agitating system has proven itself effective many times over in combination with direct filling from wheeled loader buckets through a loading chute.

POTENTIALLY EXPLOSIVE ATMOSPHERES

The agitators are available with various ATEX, IECEx and UL/CSA ignition protection types for use in explosion protection zones 1 or 2.

MIX-IN PERFORMANCE VALUES ACCORDING TO REQUIREMENTS

With our extensive range of different impellers, drive powers and installation options, we can supply customised solutions to meet your particular agitation needs. One or more agitators are used depending on the tank shape, substrate properties and method of filling. References are available for agitation rates of up to 40 tonnes silage and solid manure per hour.

LOW SELF-GENERATED ELECTRICITY REQUIREMENT

The efficiency of our agitators is maximised by the large propeller and low frequency-controlled speeds. This is the only way to minimise the energy needed to convert electrical energy into agitation or circulating rate.

EASE OF SERVICING

Important wearing parts are mounted externally and are easy to access. It is therefore not necessary to remove the agitators or to climb inside the tank for maintenance and service work.

HIGH RELIABILITY AND LONG SERVICE LIFE

streisal Maischebull®/Hydrobull® agitating systems are characterised by great robustness and long service lives. Many of the components used have proved reliable in practical application for more than 30 years. With wheel loaders, wear-prone solids metering units are also not necessary during filling.